Features

| Name | Detail |

|---|---|

| Power Supply | 3 ∼ 400V, 50/60 Hz CEE 16 A |

| Evacuation time | < 60 sec (20 mbar) |

| Residual vacuum val. | up to 1 mbar |

| Working area XYZ (mm) | up to 1000 x 350 x 150 |

| Max load on axis table (kg) | 100 |

| Maximum Piece/Pallet dimensions with XYZ axis (mm) | 200/400 x 330 x 150 |

| Compatible metering heads | DOP piston metering head, 1-4 folds |

| Safety | Safety PLC (SIL-3) |

| Dimensions (WxDxH) in mm | 1131 x 742 x 2116 (1C) |

Description

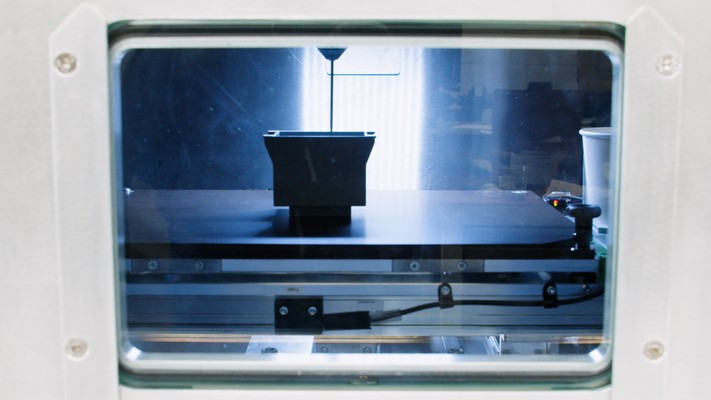

VACUA0CNC dispensing system in vacuum

Industry 4.0 vacuum potting dispensing cell for high-performance operations with attention to detail and advanced features:

- AISI 304 stainless steel chamber, resilient and durable.

- Piston volumetric metering head (DOP) for a precise dispensing, including multi-nozzle capabilities.

- Vacuum monitoring with precise pneumatic solenoid valves, for a vacuum level down to 1 mbar absolute.

- Motion and dispensing interpolation for a simplified and repeatable process.

- Remote control via SCADA and/or PLC.

- Quick production changeovers thanks to sophisticated software, compatible with all browser-equipped devices.

- Integration with factory computer systems and other machines.

- Teach programming with joystick (JOG).

- Integrated weight control (BIL).

- 3D G-code proprietary programming tool (G-Sketcher).

- Temperature management (RIT).

- Management of external feeding systems (vacuum tanks),

MAIN APPLICATIONS

The system enables encapsulation of a wide range of components, including transformers, windings, sensors, capacitors, PCBs and mechanical componetns with silicone oil, such as linear and rotary dampers.

INDUSTRIAL FIELDS

Our system has been successfully adopted by major international industrial leaders in a wide range of sectors, including electrical, electronic, automotive, aerospace, chemical and medical.

PRODUCT FEATURES

The 4.0 solution featuring a welded AISI 304 stainless steel chamber, handles self-leveling resins, including those with fillers, polyurethanes, epoxies and silicones. It integrates piston heads (DOP), with multi-nozzle operations, to optimize production process and timing.

- Welded AISI 304 stainless steel chamber with tempered glass top view.

- Pneumatic front door with tempered glass.

- Internal LED lighting.

- Multi-axis interpolated CNC system for handling and dispensing.

- ISO G-code programming with dedicated commands for vacuum level and dispensing.

- Display of time/pressure cycle charts for detailed operations monitoring.

- Pallet presence and positioning sensors.

- Safety PLC, position sensors (SIL-3).

- Remote control via dry-contacts and TCP/IP.

- Industry 4.0 certifiable.

- Integration with factory computer systems (ERP/MES).

- 3D G-code programming tool (G-Sketcher).

OPTIONALS

- Single or multi-nozzle (DOP) for maximizing productivity.

- Integrated material preparation management.

- Use of joystick for teach programming mode (JOG).

- In-line solution with double automatic door and automatic loader to optimize workflow.

- Integrated weight control (BIL).

- Pre-heat temperature control.

- I/O for vision system and quality control (barcode).