More than three decades of R&D for the manufacturing industry

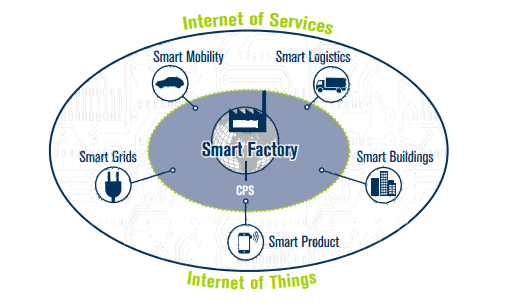

For over 30 years ATRA s.r.l. has been engaged in the research and development of innovative solutions for industrial production and, in particular, in the development of dosing systems, preparation and dispensing of resins, impregnation, gluing and sealing solutions. Working in close contact with the customer, we design and produce systems for dispensing 1/2 components resins for complex industrial applications in atmosphere and vacuum, where the ability to integrate these technologies within the customer's production lines effectively and efficiently, it makes the difference. The effectiveness of application solutions doesn't just depend on the machine’s hardware, but increasingly also on the customization and integration of the software within the customer's IT infrastructure. For this reason, all the ATRA’s machines are native 4.0, equipped with an integrated AP and are able to communicate with management systems (MES, ERP, ...) according to internationally validated protocols, such as HTTPS or SSH, and military grade AES encryption standards -256.

During our fast evolution we have developed special machines, software, systems and applications for various sectors, including household appliances, electronic and electromechanical components, ophthalmic and automotive.

We are here to help you.

Our history

Based on our recent expansion, we are able to offer a vast and complete package of services, starting from support during the product design phase, to testing and preliminary sample production, up to the delivery of the final production system. Focusing on Industry 4.0 and Smart Factory concepts for interfacing the production plants (e.g. cloud-based software for production monitoring, statistics and traceability), we are able to define the optimal processes for achieving your project's goal.

After starting a collaboration with Scheugenpflug AG several years ago, the Germany-based world leader in precision dispensing systems for mono and bi-component resins, we have added to our activities the distribution and customization of their products in Italy and several other foreign markets (Switzerland, Slovenia, Croatia, Serbia, Turkey).

Our Laboratories and Application Center

Our customers can take advantage of our experience gained during many years in the business: we can offer assistance starting from product design, the choice of the type of resin and application technologies to use, the definition of aditionally needed production processes, up to the planning and establishment of the whole production process.

Are you developing and designing a new product?

- We can help and support you in optimizing the product for dispensing processes, which will simplify the production equipment and lower the production cycle times.

Are you in need of prototypes for process validation and samples for stress tests?

- In our prototyping and sampling shop we can produce the needed parts using equipment very similar to the final production machines and simulating the "real" production processes.

Do you need to resolve failures and improve the overall product quality?

- In our chemistry lab we can analyze the parts and help you understand the reasons behind the failures. In addition we can apply additional processes to improve the process quality and eliminate the failure cause (pre-heating and drying, surface treatment and cleaning with plasma, primer application, etc.)

The production process is validated and you need to deliver first products until your final production equipment is ready and installed in place?

- We can produce the parts for your customer using the same production technology and processes as validated.

You want to improve your quality product and enhance it with an exclusive sound?

- In our fully equipped acoustic lab we can study and work on the acoustic design of your product. With our experience in mechanics and chemistry we can design and propose innovative resin applications to make your product "sound" better.

Quality Policy

Our Quality Policy aims to enhance customer confidence by operating in full compliance with current regulations. To achieve this goal, ATRA is committed to implementing the global strategy designed by the Management, a tool to guide the company towards continuous improvement of its performance.