Introduction

The fact that we understand and dedicate our business to the full industrialization of new products, leads us to consider production processes as a whole. In many cases, the condition of the surface and the material compatibility is not taken into consideration, creating in the worst case considerable quality problems, i.e. bad or no adhesion, leakages, low wetting, etc.

The verification of the surface tension and the appropriate surface activation (plasma, corona, etc.) help to improve adhesion and wettability with benefits for further processing.

In other cases, plasma processes combined with particular conditions (additives, inert gases, etc.) can be applied to increase the surface tension and to obtain a self-cleaning-like effect, reduction of adhesion, wettability and long-term sterilization.

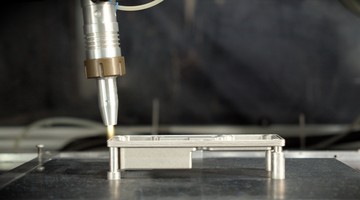

Atmospheric plasma technology allows cleaning, activation and coating of surfaces of almost all kind of materials: plastics, metals, glass and even cardboards, textiles and composites and can be easily integrated inline in a production line.

Low cost and even incompatible raw materials can be used and combined together, to reduce the costs of the products and finally to render the manufacturing process more efficient and environment friendly.

Plasma and corona treatments

Today plasma physics is a top-notch technology, acknowledged as industrial process for the treatment of surfaces, replacing the traditional application of primers and nanotechnology.

Here are some of the most common cases where plasma surface treatment is applied to increase performances:

- Bonding and adhesion

- Gasketing and sealing

- Painting

- Screen- and pad printing

- Surface micro-cleaning

- Sanitation and sterilization

- Elimination of release agents and contaminants

PlasmaCoat 3D

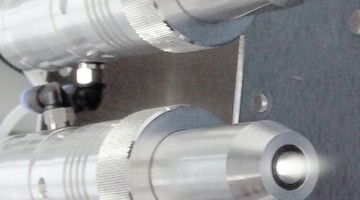

PlasmaCoat is the revolutionary dry metallization process for high volume electronic products like cellphone antennas, LED modules, semiconductors and printed circuit boards.

The technology is designed for high volume and cost efficient production of polymer based modules on 2D and 3D substrates. The key is the dry (no chemistry involved) and ROHS/REACH compliant metallization process of different polymers, metal or ceramic substrates.

PlasmaCoat integrates all the advanced features and production steps, required for mass production of electronic products: from molding, cooling, lacquering, UV-curing and plasma metalizing to quality inspection. Its functionality, speed and design is setting new benchmarks in the industry.