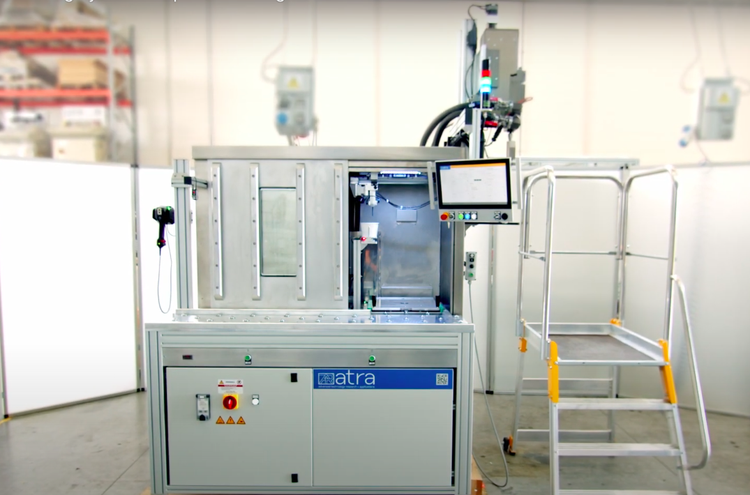

Atra at Coiltech 2024

On Wednesday 18th and Thursday 19th September 2024, Atra will exhibit its systems at Coiltech - International Coil Winding Exhibition Italia 2024, the international fair of materials and machinery for the production of electric motors, generators, transformers and windings. Come and see us in Hall 5 Booth A33. Book your free ticket at this link and get in touch to let us know you will be there: info@atra.it, or contact your sales representative.