Features

| Name | Detail |

|---|---|

| Dimensions WxDxH | 1.410x1.350x2.500 mm |

| Working area | with drawers 500x500x150 mm, without drawers 500x500x300 mm |

| Max speed CNC | up to 300 mm/s |

| Transportable weight | up to 18 kg |

| Power supply | 3F + N + T ~ 400 V / 50 Hz |

Description

AERIA0draCNC system with cartesian kinematics robot and interpolation between motion and dispensing. This system offers:

- Management of mutiple dispensing heads (DOP pistons, DOI gears)

- Interpolation between motion and dispensing for a simplified and repatable process

- Remote control via SCADA and/or PLC

- Quick production chageovers thanks to an advanced proprietary software, compatible with all browser-equipped devices

- Integration with factory computer systems

- Automated connection with the logistics system, supply network and other machines

- Teach programming with joystick (JOG)

- Integrated weighing control (BIL)

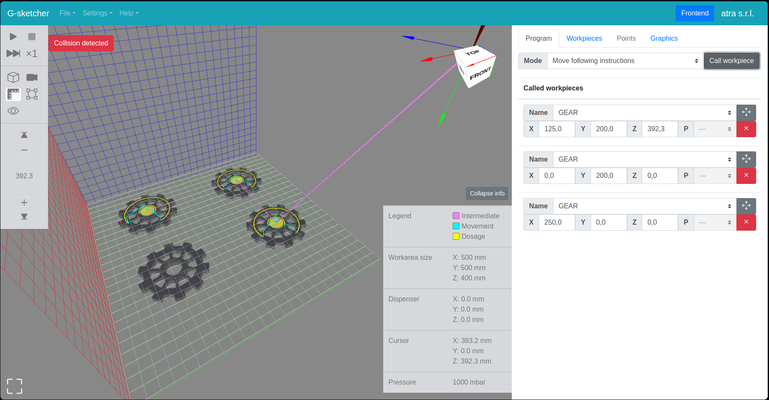

- 3D G-Code programming tool (G-Sketcher)

- Temperature management (RIT)

- Management of external feeding systems (pressure and vacuum tanks, pressure plate pumps and cartridges)

MAIN APPLICATIONS

The system enables a wide range of processes from dispensing to bonding, from sealing to the application of thermally conductive materials.

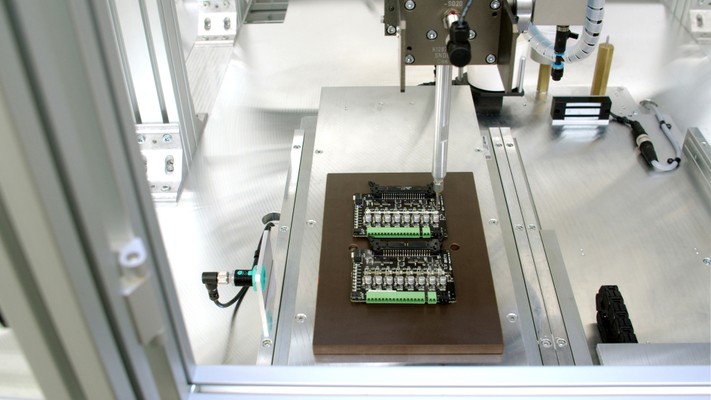

- Potting of electronic components of various siszes, including PCBs, sensors, transformers, coils, stators, connectors, wiring

- Gaskets and seals for electronic enclosures

- Suitable for variable bach sizes and dispensing of thermally conductive and thermosensitive materials

- Capability for surface treatments using a plasma torch

INDUSTRIAL FIELDS

The system is successfully employed by leading international industrial players in the electrical, electronic, automotive, aerospace, chemical, medical sectors.

PRODUCT FEATURES

- Multi-axes CNC with motion and dispensing interpolation

- Embedded controller and user-friendly multi-devide HMI interface (CON)

- G-Code programming

- Presence and pallet positioning sensors

- Safety PLC, optical barrier and positioning sesors (SIL-3)

- Remote control via clea contacts and TCP/IP

- Inudstry 4.0 certification

- Integration with factory computer systems (ERP/MES)

- G-Code software for 3D programming (G-Sketcher)

OPTIONALS

- Different metering heads with interchangeable piston pumps (DOP) or geam pumps (DOI)

- Quick head changeover campability

- Choice between single or multiple nozzles (DOP)

- Integrated material preparation management

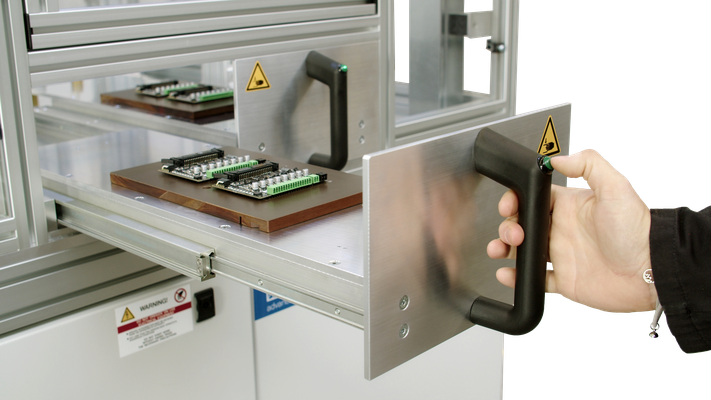

- Handling on spherical surfaces or with drawers

- Joystick for teach-mode programming (JOG)

- Plasma unit implementation

- I/O vision systems and quality control (barcode)