Description

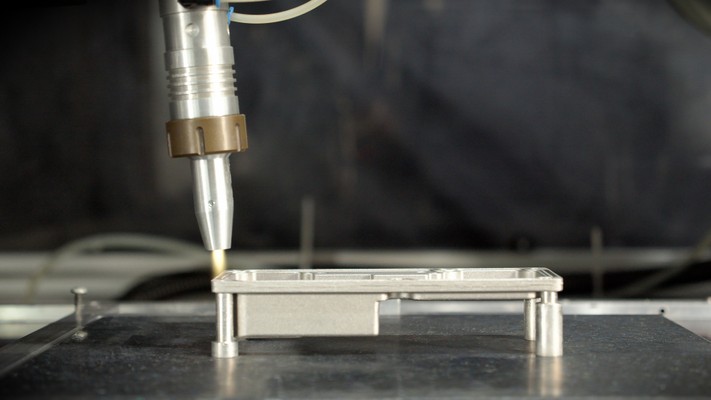

MCP plasmaAdvanced surface treatment with Micro Cold Plasma

Micro Cold Plasma (MCP) by our exclusive partner Inocon is suitable for optimum surface cleaning and surface activation, especially on extremely sensitive substrates. Surface activation via plasma is very effective on synthetic materials whose structure is often nonpolar and have to be pre-treated. The atmospheric MCP-Technology enables the cleaning, activation and coating of surfaces with plasma of almost all the possible materials: from plastics to metals, glass, even carton, textiles and composites. Our MCP-Technology systems are specifically design for high demanding industrial continuous operations and ensure a perfect integration in production lines. The optimised plasma jets feature high power density plasma and low gas or air consumption. All MCP–systems can be set accordingly with the process conditions and the substrates via the operating parameters, in order to treat the surface in the most cost-effective way.

MAIN APPLICATIONS

- Selective surface activation before imprinting, gluing or paintwork

- Gluing of various materials

- Pre-treatment of injection components

Gluing process:

- Nearly all synthetic substances can be treated

- Gluing of various materials

Coating process:

- Better adhesion of the coating

Printing process:

- Consistent plasma treatment over the whole surface

- Better adhesion properties

- Long-lasting surface resistance

ADDED VALUE

- Increased surface tension for a perfect adhesion and printing

- Minimum energy input and thermal load on the substrate

- Works in atmospheric pressure: no vacuum, no special atmosphere

- Good wettability for disinfection and perfect adhesion

PRODUCT FEATURES

- Special nozzle geometry allows perfect access to any workpiece

- Space optimization due to compact power electronics and longer hose

- Lower temperatures at the nozzle (max. 255°C)

- High process speed

- High nozzle operating life (min. 400h)

- Low-maintenance continuous operation