Description

Resin compounds are nowadays used for many different purposes and their application fields are increasing every day.

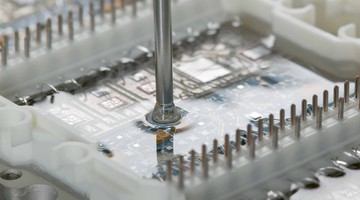

Potting and encapsulation is the process of embedding electronic components & assemblies in a liquid resin (potting compounds) to protect them against rough environment conditions. Potting can be performed in atmosphere pressure or even under vacuum, if high voltage insulation and high temperature differences are needed. Encapsulation of parts will stop corrosion of metals and reduce damage caused by vibration and mechanical stress.

Sealing is the process in which resin beads (liquid gaskets) are applied to housings (electronic control units, lighting, air ducts,...), before they are being joined together. Depending on the application, sealing beads can be used also for bonding of the housing parts and to replace additional screwing processes.

Gap filling and thermally conductive pastes application are quite new processes in automation production, to replace the manual application of thermal pads. These applications are getting more important, as thermal management in electronic parts is a challenging issue due to the miniaturisation of the components and their increasing performance.

No matter what your resin application requirements look like - we can do most of them in our fully equipped lab.

We can handle 1- and 2-component polyurethanes, epoxies, acrylics, silicones - temperature, humidity and UV curing materials. They can be from low- to high-viscosity, filled or unfilled and even high abrasive for thermal conductivity.

Resin Application Services Provided

- Resin material selection & testing

- Prototype design & production

- Potting and encapsulation in protective atmosphere

- Vacuum potting and encapsulation

- Sealing and bonding

- Thermal paste and gap filler handling

Benefits

- Low cost part fixtures or molds

- Prototypes with real production equipment

- Process optimization

- Quality enhancement with additional processes:

- surface treatment with plasma and corona

- preheating / drying and curing