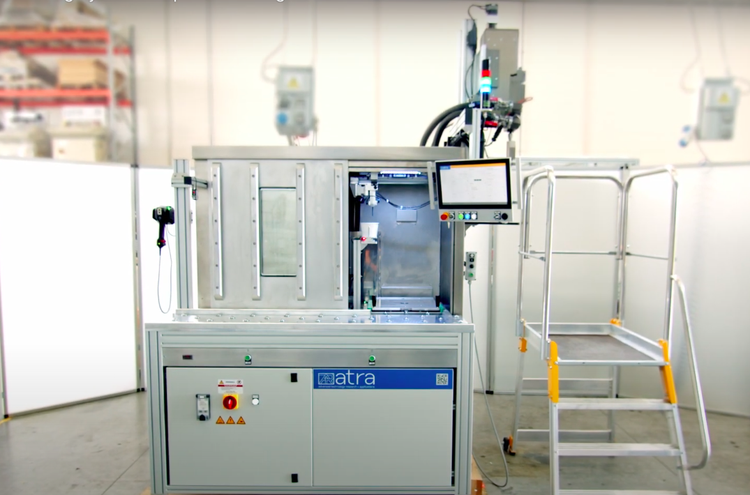

We have recently delivered a new system, specifically designed for working on large stators of electric motors. It consists in a LiquiPrep for mixing and degassing A and B materials, a P300 metering head with recirculation system (both by our exclusive partner Scheugenpflug) and a custom-made vacuum chamber in AISI 304 stainless steel.

The metering head can reach a 30 ml/sec flow rate and is able to constantly and accurately dose volumes up to 190 ml/shot. The mixing ratio is always guaranteed by the mechanic of the pistons. A laser pyrometer allows the temperature control of the pre-heated piece, while a 1D/2D code reader allows identification and traceability of the piece.

Inside the chamber you can find the mobile nozzle (with anti-drip) on the X and Y axis system, the purge cup with filling sensor and a piece positioning sensor. The autonomous Z axis allows to lift pieces up to 100 kg. The entire system is managed by a web based interface for remote control and real-time process monitoring: straight or curved paths can be programmed in G-code, even via joystick for a simplified position acquisition. Industry 4.0 technologies allow easy integration with pre-existing systems and management software.

Have a look to this and other video on our TouTube channel!