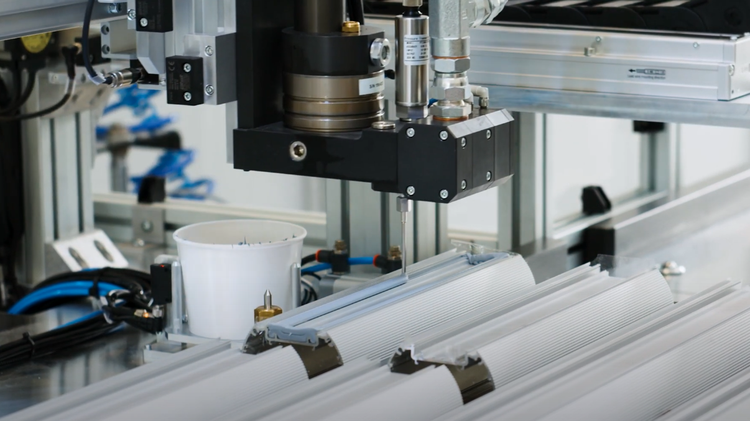

In the last quarter of 2021, we developed an automatic dosing system for an important multinational customers of ours, leader in the design and production of electrical equipment for environments with risk of explosion and fire.

This system features an interpolated CNC with volumetric gear dispenser. The metering of the material (in this case, single-component) takes place through a high pressure valve that can work up to 100 bar. The P.I.D. regulation of the material feeding pressure manages the follower plate.

The double pallet allows you to maintain high productivity, while the centering and selection pistons always guarantee their perfect positioning. The 1500 mm X axis allows you to work large pieces, while the Y axis features two high-precision motors.

The user interface, simple and ergonomic, is also remotely accessible and allows easy programming through the ISO G-Code system. Industry 4.0 technologies are integrated, with TCP-IP protocol suite and safety PLC.

You can find the video of this project on our Youtube channel.