Features

| Name | Detail |

|---|---|

| Safety Features | Front door with safety switches |

| Typical dispensed products | Oil, grease, glue, silicon, paint, flux, medical products, and many other chemicals. (Filled products included) |

| Heating capacity | up to 80 °C |

Description

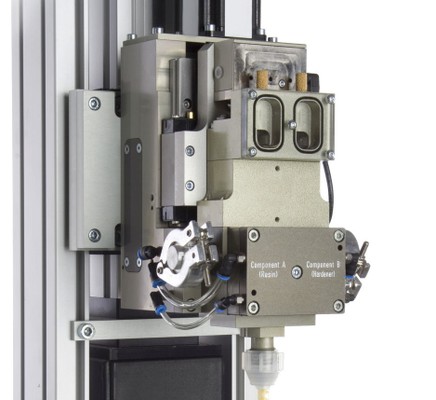

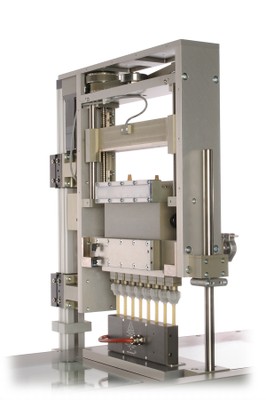

VA10002High precision dispensing system with reliable and constant mix ratio for highest process safety

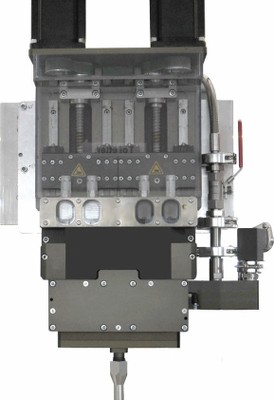

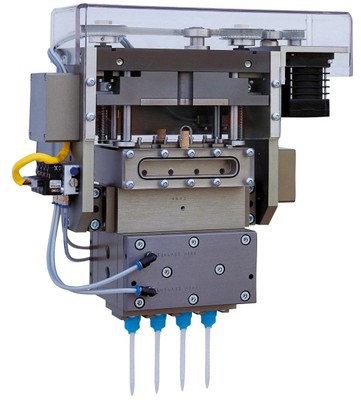

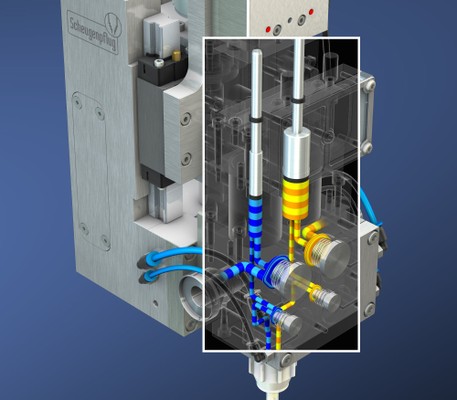

The DOS P metering head is a volumetric piston dispensing system for one or two component materials, based on a standard design. Each metering head is then customized to meet the required process specifications in terms of mix ratio, dispensing quantity and number of nozzles. The mix ratio is mecanically established through the diameters of the resin and hardener cylinders and guaranteed by the simultaneous movement of the metering pistons. The constant and repeatable dispensing quantity is defined by the pistonsstroke, which are moved by a stepper motor. The system works with the fixed volumes of the metering cylinders for resin and hardener in the metering head and it separes the defined volumes from the feeding systems by closing the inlet valves: this makes sure that the dispensing is completely indipendent from feeding pressures, material viscosities and temperature.

The material components are always kept separated inside the metering head, until they meet in the disposable static mixing tube, where they are blended.

The metering pistons touch the dispensing material only on one side, pushing it ahead and cleaning the cylinder walls during each stroke. The protective liquid on the back side of the pistons helps to clean and remove agressive and abrasive parts from the seals and the cylinder walls, and seal the dispensing material from contact with atmosphere and moisture. It helps to efficiently minimize wear, drastically reducing maintenance costs.

Equipment features:

- Stepper motor driven.

- Pneumatic inlet and outlet valves with diaphragm.

- Magnetic sensors for piston rod monitoring.

- Sight glasses for protective liquid inspection (quality and level).

- Mixing nozzle / dispensing needle adapter.

Optional:

- Servo motor driven with closed loop encoder.

- Tungsten inlet and outlet valve inserts for abrasive materials.

- Inlet valve monitoring.

- Single nozzle control.

- Heater for metering head.

- Heater for mixing nozzle / needle.

Variants:

- DOS P016 - 1C or 2C.

- DOS P050 - 1C or 2C.

- DOS P100 - 1C or 2C.

- DOS P300 - 1C or 2C.

- DOS Px vacuum - multifold.

- DOS PA alternating - continuous dispensing.

- DOS P016 - TCA - Optimised for highly filled dispensing materials.

- DOS P016 - DP803 - compact version of the P016 (TCA available).