Description

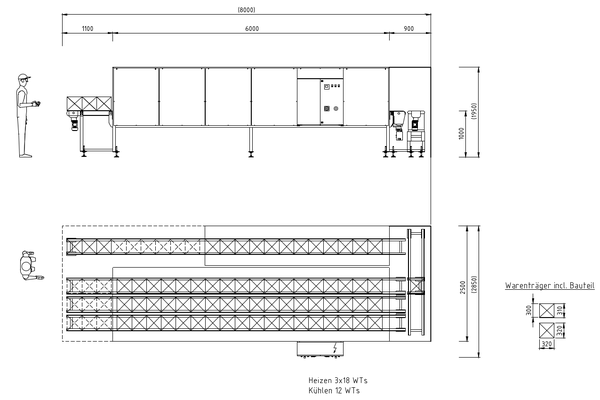

oven1-RAutomatic horizontal continuous oven with forced air ventilation, designed to treat materials that require polymerization process. The process is achieved by uniform temperature throughout the entire volume of the oven. The oven is placed in a special metal sheet construction. It includes three movement tracks for pallets on the heating area. The load/unload areas are placed on the same side. On each lane of the heating system there are a maximum of 18 carriers {+3 in the buffer).

Features:

- Heating up to 180°C.

- Pallets: 300x300 mm (height ≈ 200mm).

- 3 speeds movement tracks.

- Automatic pallet loader for the cooling back track.

- Polymerization heating length: ≈ 6000 mm.

- Polymerization cooling lenght: ≈ 6000 mm.

- Construction year: 2015/2016.