Features

| Name | Detail |

|---|---|

| Dimensions (WxDxH) in mm | 1131 x 742 x 2116 (1C) |

| Flow rate of piston pump per double stroke (ml) | 35 |

| Max. material feed pressure (bar) | 150 |

| Control | Multi-touch control panel with capacitive 10.1" display, EViS visualization and USB port |

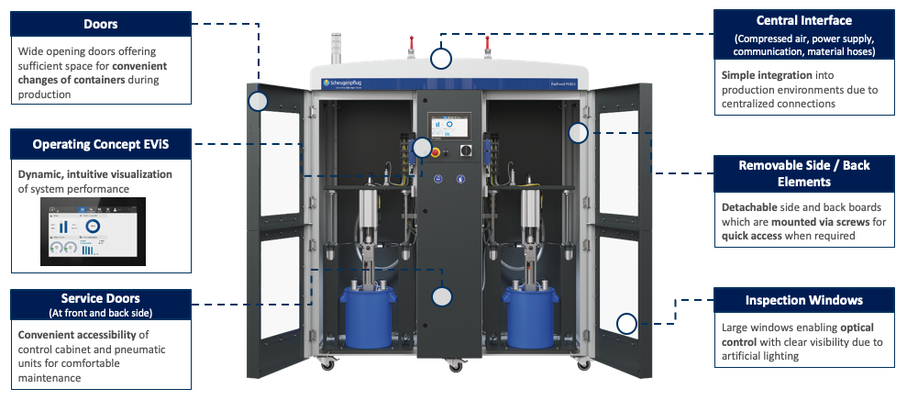

Description

PFAPF803powerful feed system for abravise and non-abrasive viscous media

Material feed must meet the growing demands for speed, sustainability and economy. The new PailFeed system ensures that medium to high-viscosity materials can be reliably and easily transported from the container to the dispensing unit.

The new solution is a perfect combination of a robust piston pump and Scheugenpflug's patented vacuum follower plate system. It ensures bubble-free docking with the container by extracting the cushionof air between the surface of the material and the follower plate. This fully automated docking process reduces material loss and saves time when changing containers. There is also less cleaning to do because the vacuum follower plate is disposable and remains in the container after the container has been undocked.

Stable, state-of-the-art control technology and components ensure that the pail is automatically monitored and that constant material feed pressure is maintained.

The PailFeed can hadle a wide range of dispensing pressures. There are three different material pressure ranges tailored to the dispensing unit. It delivers up to 150 bar for the new high-performance dispensers. Several dispensers can be supplied in parallel, quickly and over long distances.

SIMPLE DOCKING

- Convenient loading thanks to standardized loading mechanisms and flat loading surfaces

- Infinitely adjustable contact pressure, automatic control according to the position of the follower plate

- Adjustable expansion ring for optimum sealing of conical containers

DIGITAL PROCESS MONITORING

- Ergonomic location at eye level

- Widget-based graphical user interface

- Touch functionality

- Continuous automated monitoring of key parameters

- Data capture for subsequent analysis