Potting/Casting products of different sizes in a vacuum chamber that's integrated in an automated production line has always been quite challenging, more so for large production quantities. When faced with that kind of setting, our engineering team has put together all the knowledge and experience acquired throughout many years to design an automated production line that covers all of the above requested needs.

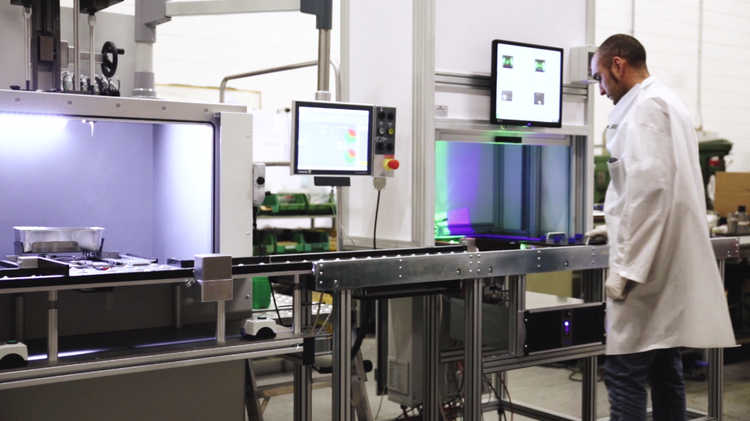

Comprising an alternating volumetric piston metering head for continuous, uninterrupted dispensing resin flow, an inline vision system equipped with HR cameras for product type/position recognition, infrared cameras for temperature monitoring of the products and an inline VDS vacuum chamber that features appropriate CNC movement and reads via Ethernet TCP/IP connection the previously collected data to automatically choose the specific dispensing recipe, this automated production line assures a smooth and safe dispensing process with minimal supervision needed.

Additionally, each process station within this production line can be easily connected to a factory host computer system and provides all necessary data for product traceability and Industry 4.0 production monitoring, making them fit for a smart factory context.